- Epoxy Primers

- Epoxy Paints

- Polyurethane Primer

- Polyurethane Paints

- Enamel Primers

- Enamel Paint

- Alkaline Degreaser

- Universal Cleaner

- Aluminium Chromating

- Etch Primer

- Rust Converter

- Hot / Cold Phosphating

- De-ruster

- De-watering oil

- High Temperature Silicone Paints

- Chlorinated Rubber Paint

- Acrylic Vinyl Paint

- Zinc Silicate Coating

- Water Based Anti-Corrosive Paint

Contact us

For Business Opportunities, Product Purchases and Application Services

Anti Corrosive Coatings and Paints

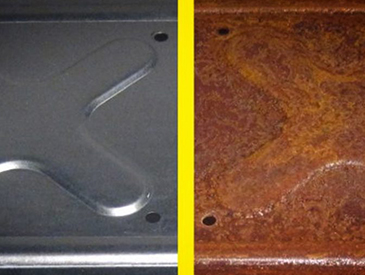

Rust Converter

Rust converters are usually applied to objects that are difficult to sand blast, such as vehicles, trailers, fences, iron railings, sheet metal, and the outside of storage tanks. It may also be used to restore and preserve iron-based items of historical importance. Commercial rust converters are water-based and contain two primary active ingredients: tannic acid and an organic polymer. Tannic acid chemically converts the reddish iron oxides into bluish-black ferric tannate, a more stable material. The second active ingredient is an organic solvent such as 2-butoxyethanol (ethylene glycol monobutyl ether, trade name butyl cellosolve) that acts as a wetting agent and provides a protective primer layer in conjunction with an organic polymer emulsion.

Some rust converters may contain additional acids to speed up the chemical reaction by lowering the pH of the solution.

A common example is phosphoric acid, which additionally converts some iron oxide into an inert layer of ferric phosphate. Most rust converters contain special additives as they support the rust transformation and improve the wetting of the surface.

Our Application Services

Advanced Technology

Application Experts

Commitment to Quality

Request a Quote

Please use the form below to send us your projects and comments. We appreciate you taking the time to provide us with your views so that we can best meet the needs of you. We aim to provide a seamless experience to all our users.